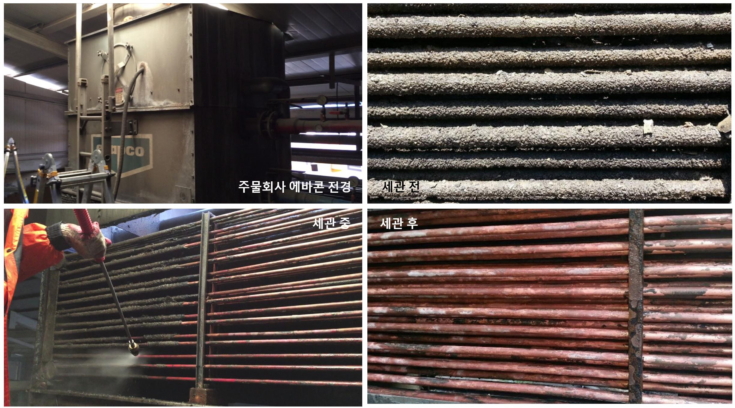

(Korea Newswire) December 1, 2015 -- NCH Korea today announced that it is launching ‘EvaCon(Evaporative Condenser) Washing Service’, which is for removing scales from Evaporative Condenser.

‘EvaCon’ or Evaporative Condenser, is an equipment that condenses ammonia gas, which is a refrigerant. As it sprays and evaporates water on the surface of zinc plating pipe, scales are created on the surface of the pipe. Scales increase the pressure of ammonia gas, therefore, also increase electricity cost.

Until now, acidic washer is used to remove scales from Evaporative Condenser, however, acidic washer has created severe damages on zinc plating, as well as corrosion in the pipes. Evaporative Condenser needs to be replaced when corrosion happens, however, it required too much cost and time to do so.

NCH Korea’s ‘EvaCon(Evaporative Condenser) Washing Service Program’ combines the advantages of decomposition using chemical products and machinery crushing, therefore, effectively removing scales formed on EvaCon. In particular, as it uses alkine and neutral chemicals, it can be safely used on various types of pipes, such as those made of zinc and copper. Also, as NCH’s EvaCon(Evaporative Condenser) washing service combines chemical washing and machinery washing, this method can make up for the weak point of each, and therefore, produces excellent results.

First step for NCH EvaCon(Evaporative Condenser) Washing Service is ‘chemical preconditioning process’. It uses scale softener to decrease hardness of scale, to make it easier to be crushed with machine. During this process, penetration improver and microorganism remover are added together, to accelerate scale softing.

Second step is ‘machinery scale crushing’. Evaporative Condenser’s external partition is removed to let crushing ma hine reach deep inside, and ultra high-pressure washer is used to remove scales with machine. After removing scales, external partition is added back. During this process, professional packing is used to completely avoid water leak and unnecessary air inflow. If necessary, the user may choose to remove corrosion on the partition and structure, and to apply special coating or zinc plating to avoid re-corrosion.

EvaCon(Evaporative Condenser) Washing’s third step is ‘chemical processing’. During this process, scales that are still left on the surface of the pipe are removed with alkaline washer.

As NCH Korea’s ‘EvaCon(Evaporative Condenser) Washing Service Program’ uses alkaline or neutral chemicals, it may be safely used on materials used on Evaporative Condenser, such as zinc plating and copper. In particular, NCH’s EvaCon(Evaporative Condenser) Washing Service combines chemical washing and machinery washing, and removes more than 90% of sacles without any side effects.

*’EvaCon(Evaporative Condenser) Washing Service’ Demo: https://www.youtube.com/watch?v=EXXYkpyNMe8

“Scales and corrosion are often created on EvaCon(Evaporative Condenser). There is a huge demand from customers to remove scales from major facilities of companies, and therefore, NCH decided to launch this service” said JungJoon Park, NCH Service team. He added “we are now able to support our customers to safely manage their facilities, and to improve work productivity. Also, NCH’s various products and services reduce environmental pollution, and lengthen the life of various facilities, and therefore, protect our customers’ asset”.

About NCH

NCH has been a global leader in industrial and commercial maintenance products and services since 1919. Why? Because our superior solutions maximize efficiency and keep facilities and equipment running in optimum condition at reduced cost.

We are relied upon by companies in over 60 countries to solve maintenance problems with the most innovative and effective products and services, ranging from advanced drain and HVAC maintenance to specialty lubrication, industrial and parts cleaning and water treatment.

Where industry turns for solutions. Visit www.nch.com to find out more.

News Source: NCH Korea

추천